Home Automation: Electrical Safety

This is part one of some of my notes regarding Home Automation concepts. Part 2 is about planning for the future and house resale value.

Electrical Isolation/Safety

Electrical safety is very important obviously for home automation, and as well as my tendency to over-engineer, I’m often thinking about ‘what could possibly go wrong‘. One of the things I want to be able to do is isolate things if there is ever a problem (and even automate the isolation if a fault occurs where practical).

Although AS/NZS3000 is not specific regarding isolation of various items, there is quite a lot written on the subject. It specifically mentions gas appliances, but also talks about isolation for mechanical movement (fans/motors), heating, and locations affected by water and ELV devices.

The rules state you need to isolate individual items to allow for fault/repair, ensure the phase is switched (as minimum) and no semiconductor/solid-state isolation is allowed. Any switch for isolating should be labelled.

With full RCBO/RCD protection, so it is very unlikely faults or other issues will cause a shock, but with a bunch of relay and solid state switching and dimming with parts generally from various chinese manufacturers, I want to ensure that things can be turned off in a hurry if needed, and keep any fire risk is as low as possible.

“I want to ensure that things can be turned off in a hurry if needed, and fire risk is as low as possible”.

Accessible Switchboards

Note the 4 pole controllable relay (noted below), that trips all RCDs except the fridge circuit. This relay is activated by a wired smoke detector in the area.

Of course there is always isolation at a switchboard/sub-board, but this is not always immediately and quickly accessible due to multi level houses, or possibly even locked doors.

I wanted to be sure to keep all control items on our downstairs area (which is fully self-contained and potentially rentable) to circuits on a local sub-board (AS/NZS2000:2007 2.3.3.3b ). It sounds simple and obvious, but there were are couple of places it would have been far easier to mount some controls for this area off the main board. I know that if I switch this board off, then all the relevant controls for this space go off too. (There is a second sub-board in the garage for similar reasons.)

The main switchboard for the house is actually on the lower level basement area, but the main 3 phase incoming switch is quickly accessible on the common living level (actually the incoming meter box is in the lounge, such is the age of the house!)

Light switch controllers: Direct to switchboard

I generally direct connect anything on a lighting circuit to the switchboard. I’m comfortable with these directly connected as generally there are only small loads connected such as LED lighting and ceiling fans. Also, if you are using wall mounted smart switches, how else are you going to do it? These smart switches are then permanently powered from the switchboard.

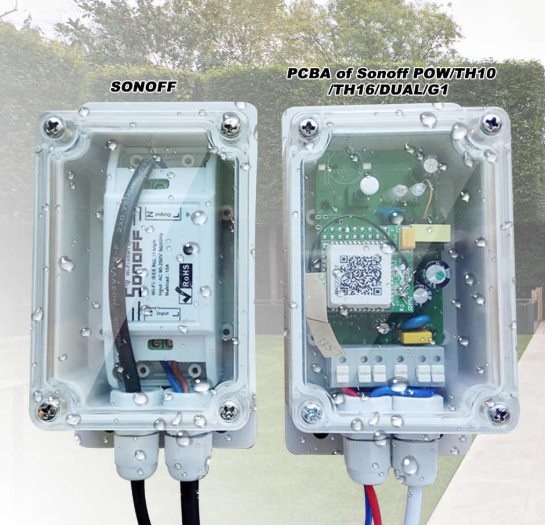

I do make sure I check the quality of every single piece of electronic equipment used (track sizes, ELV isolation, terminals, cabling, heat output) and really downrate the max loads they switch. I originally looked at devices such as sonoffs connected inline with the light switch, but when the switch is off it really limits your control options to get them back on…

In a couple of my distribution sub boards however I have put remote overrides for a bunch of circuits, including lighting (specifically for our area downstairs which is self contained and can house guests). This means that I can remotely switch the whole circuit off if a fire is detected, or we go away for extended holidays to save a few mA. (although, we’ll probably want some randomising light controls security anyway)

Power controls: Local overrides where possible

If in a room, and not just plugged into a power point (eg a lamp with built in, or inline controller), I’ve been putting local overrides in place. An example of this is the heated towel rail and room heaters in the bathrooms.

I put the override switch out of the way eg at high or low level, or with flip cover and label it. The override switches power off to the controlled item AND the controller (Generally a sonoff, D1 Mini or similar controller). As well as providing some electrical safety, it helps with control when there is no network (see the second part of this article).

Also, I’m not a huge fan of putting controllers in behind a GPO (Power points, or receptacle in US speak). Our GPOs need local switches so even if there is a controller inside there, the device plugged in can still be switched off. I have tended to use Wifi networking, so I like to make inline controllers for things like lamps and appliances, wired into the power lead and enclosed in a small box or mounted into the appliance itself. if the lamp moves to a different outlet, so does it’s control.

Accessibility

I’ve seen a lot of youtube channels where people install controllers wrapped in tape in behind switches & I personally think this is a recipe for disaster. Most devices will emit some heat, especially under load and as per the second of these two articles, you need to be sure that any future electrician does not get any surprises when they take off any switch plates.

I try to place any fixed controllers in simple individual clear lidded boxes wherever possible, either in the roof space, under the house (both of which are accessible in my place without too much trouble). The wiring is never jammed in and has wiring glanded and supported. You can see any LEDs and also if there are any wiring issues. Also, you get access any time easily (eg if OTA updates fail). Normally the boxes are sealed, but if it is an item that gives off some about of heat and it is in a guaranteed dry space, I’ll drill a couple of airflow holes in.

Most boxes are fixed in place, but some (eg lighting just sits in the ceiling and can be pulled out a downlight hole)

Summary

- Quick and easy access to switchboards and/or main switch for all locations is important.

- Provide local equipment or room overrides for power controls where possible

- Clearly label switches/Isolators (and of course controllers & wiring)

- Automate electrical safety where possible (eg fire or leak detection)

- Controllers should all be accessible, preferably enclosed in a box, well mounted, well ventilated and with supported cabling.